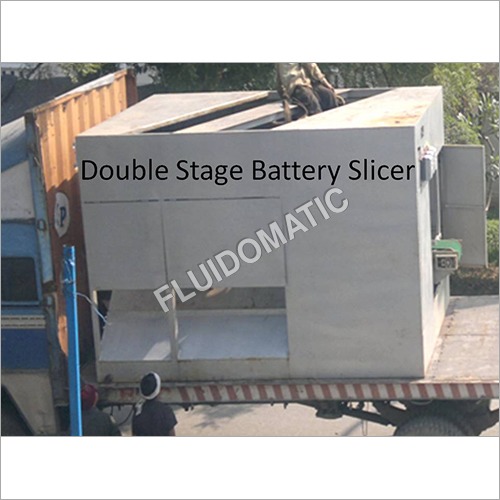

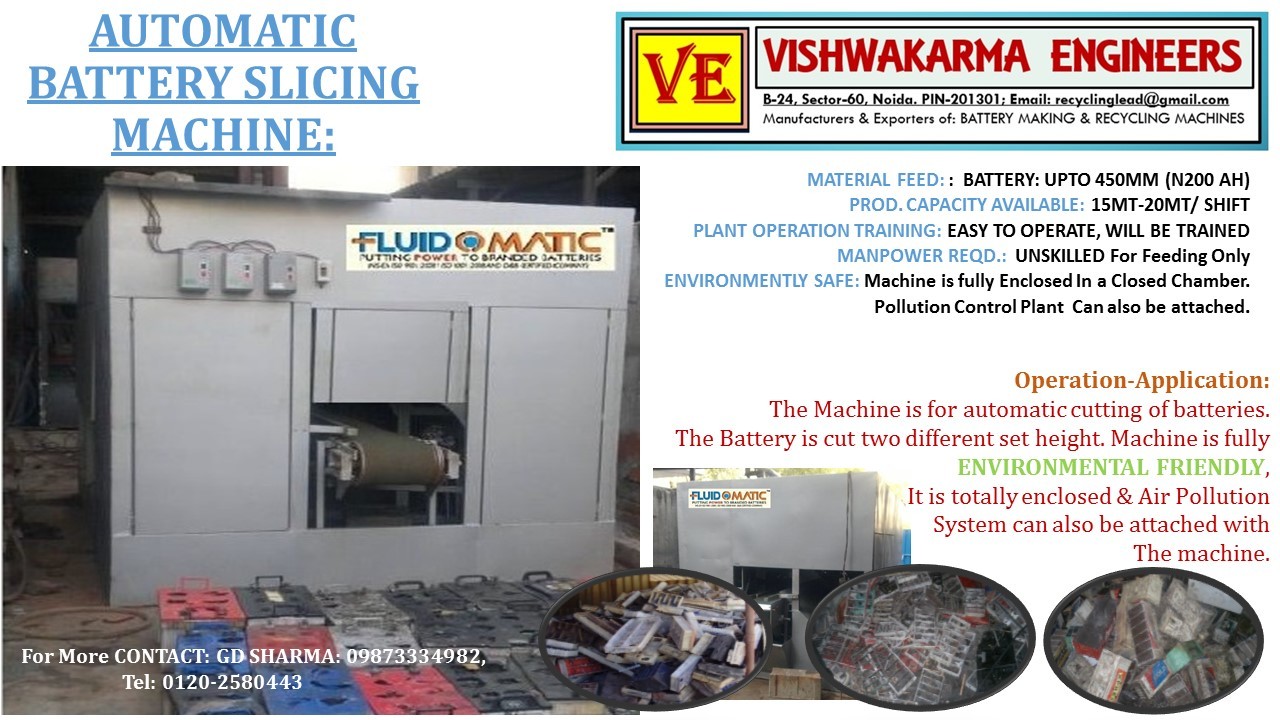

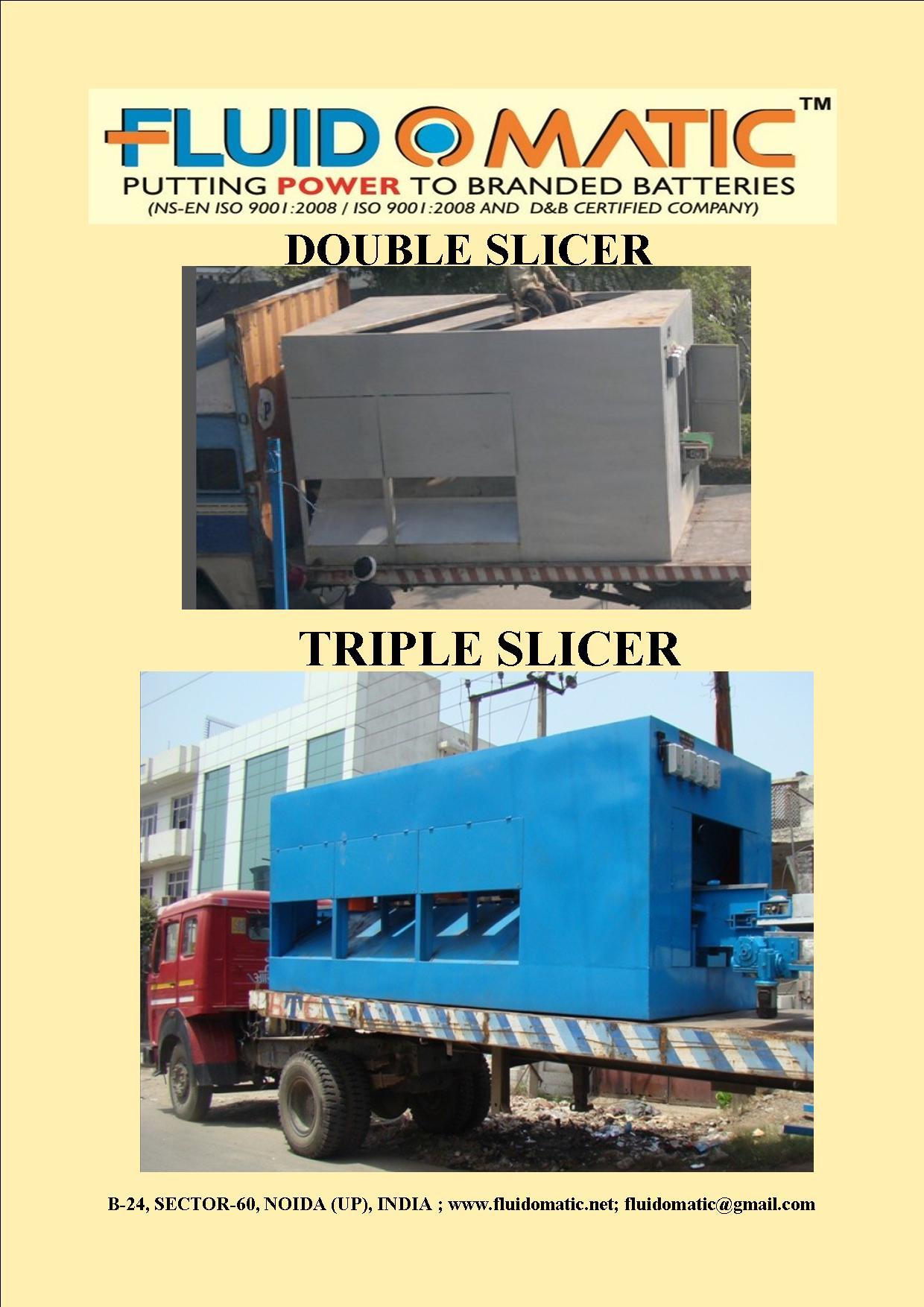

Battery Cutting Machine

Battery Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO9001:2015 , CE CERTIFIED COMPANY

About Battery Cutting Machine

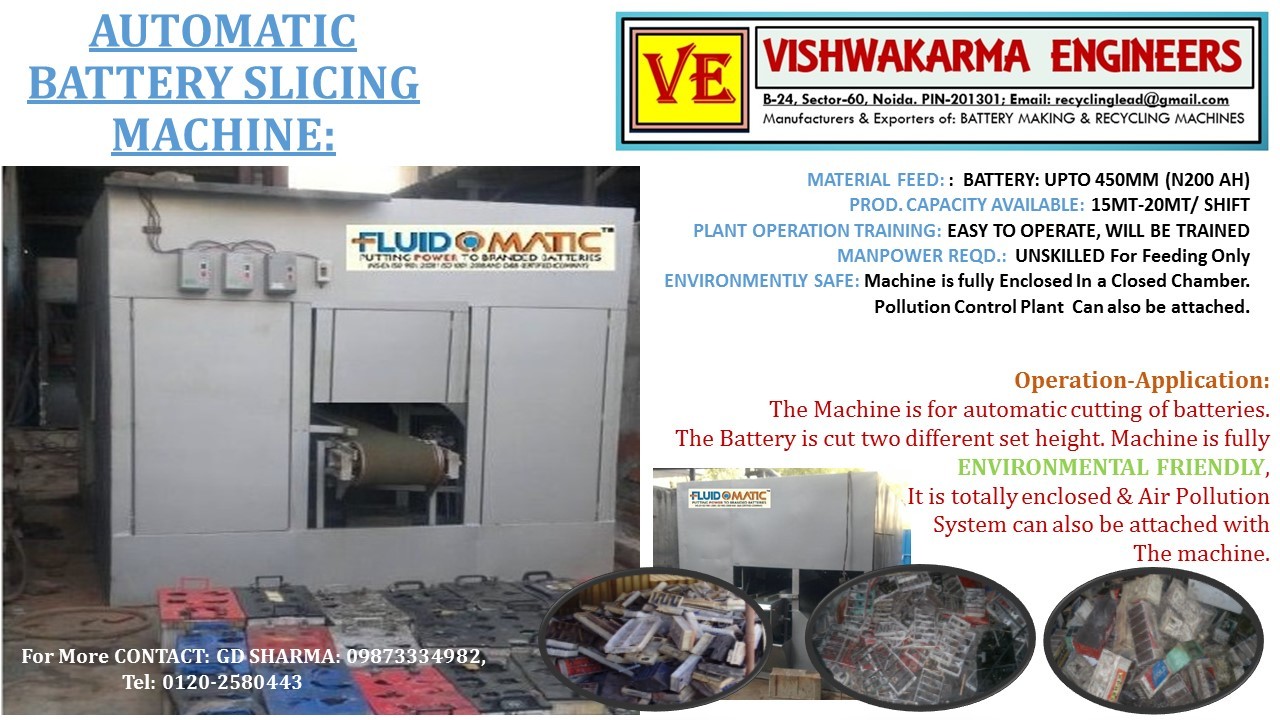

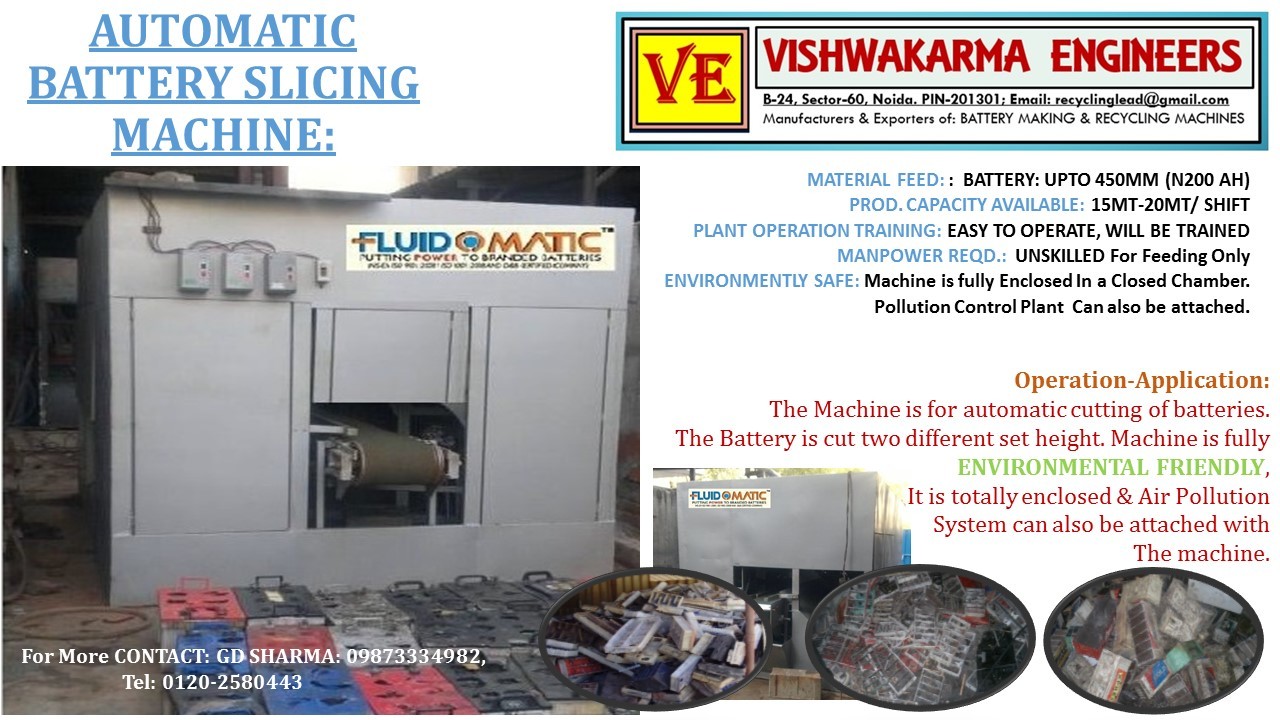

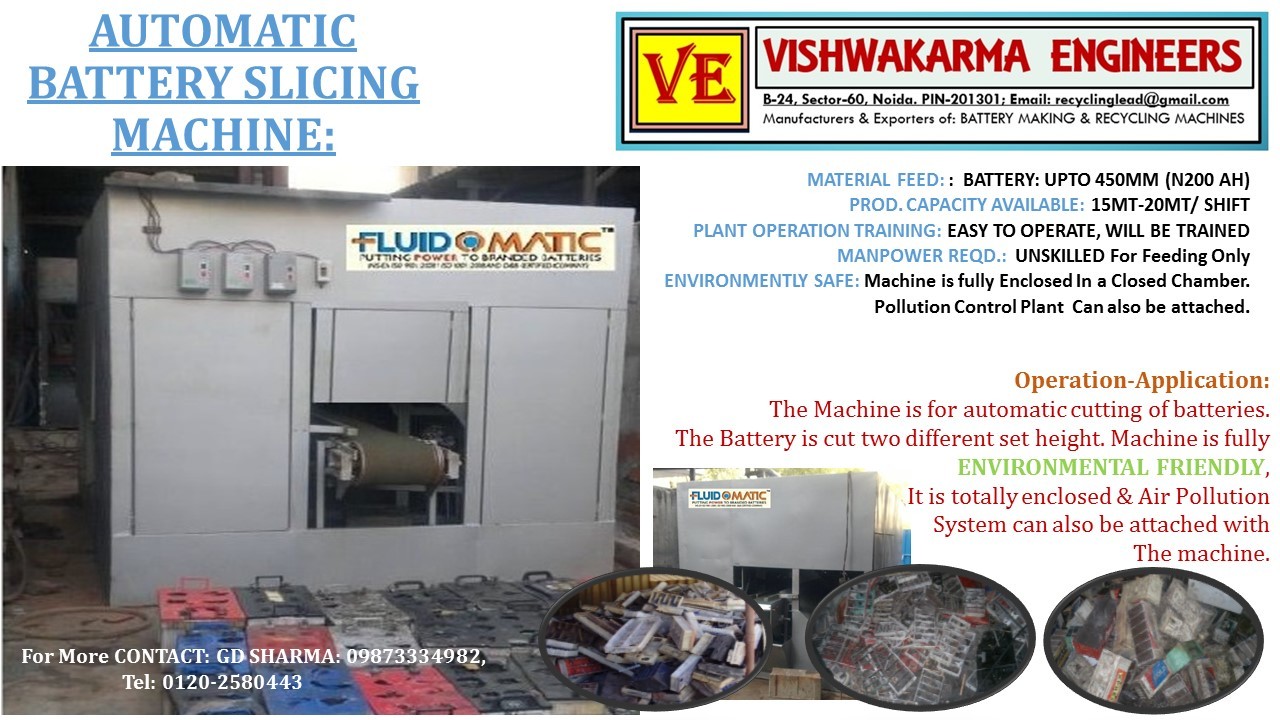

This machine has a automatic conveyor. Battery is placed on the conveyor. Width of Battery, need not to be set, battery to be placed to one side of conveyor. It can accommodate Battery up to Max.Width of 305mm. Most of Batteries are below this. Cutting height can be set by turning Rotary wheel over the machine. This wheel is visible in picture of machine. Scale is provided to set the height ofcutting. Conveyor takes the Battery in machine for cutting. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. No Fumes are coming out of the machine this ensureshealth safety of operator & labor loading the battery on machine. Normally Cutting is set at sealing line of lid. Max. of Automotive Batteries have approximately same height, say +-10 mm. Remaining Battery will come out of machine on Conveyor. If any Acid splash it will be inside the machine, therefore the acid can be taken out later on & sent to recycling in separate Acid Recycling Plant.

Thesesafeties saves exposure of workman from Lead Dust; It increases efficiency of organization reduceslead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility in Plastic Crushing Unit . Lead Dust is confined inside enclosure at the sametime water jets are provided by pre-fitted Pump for proper cooling to the cutting mechanism. Wateris collected in the bottom tank. This helps to separate Plastic Dust from Lead dust. Plastic dust floatsand lead dust is precipitated at the bottom. Hence this mechanized process becomes environmentallySound Method to cut the Battery for further separation.

Product details

| Belt Material | Nylon |

| Frequency | 50-60Hz |

| No of Cutting Blades | 1 |

| Phase | Three phase |

| Country of Origin | Made in India |

| Voltage | 415 V |

| Surface Finishing | Paint Coated |

| Power | 4.5 kW |

| Material | Mild Steel |

| Brand | Fluid-O-Matic |

| Capacity | 5 ton/hour |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Battery Plant Equipments Category

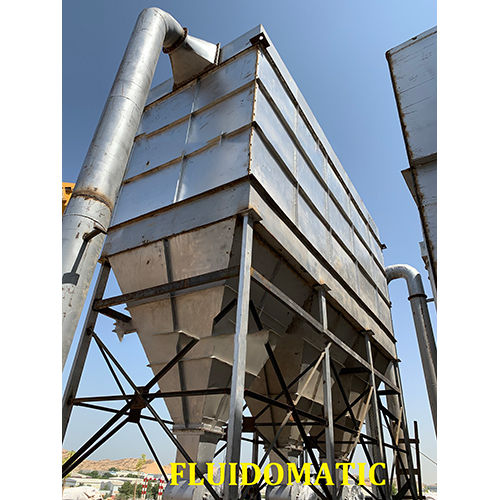

Air Pollution Control System Bag House Filtration System

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Operating Type : Automatic

Warranty : Yes

Color : Silver

Air Pollution Control Plant Venturi Scrubber

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Operating Type : Automatic

Warranty : Yes

Color : Blue paint Coated

Cremation Furnace Incinator

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Operating Type : Semi Automatic

Warranty : Yes

|

FLUIDOMATIC

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |