Battery Cutting Machine

Battery Cutting Machine Specification

- Production Capacity

- 60-90 pcs/hour

- Connectivity Options

- Panel Interface

- Accuracy

- 1 mm

- Cooling System

- Water-cooled

- Features

- High precision cutting, Energy efficient, Safety guards

- Model No

- BCM-2100

- Lubricating System

- Automatic

- Frequency

- 50 Hz

- Motor Power

- 7.5 HP

- Operating Temperature

- 5C - 45C

- Plastic Processed

- Battery casing

- Frame Type

- Heavy Duty Steel Frame

- Control System

- PLC Control Panel

- Noise Level

- <75 dB

- Voltage

- 380 V

- Power Rating

- 7.5 KW

- Machine Type

- Battery Recycling Machine

- Drive

- Hydraulic Drive

- Product Type

- Battery Cutting Machine

- Technology

- Automatic

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 5-10 kW

- Pressure

- Hydraulic / 200-300 bar

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 2100 x 950 x 1650 mm

- Weight (kg)

- 1200 kg

- Color

- Blue-Grey

- Usage & Applications

- Lead acid battery cutting, Battery recycling plants

Battery Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO9001:2015 , CE CERTIFIED COMPANY

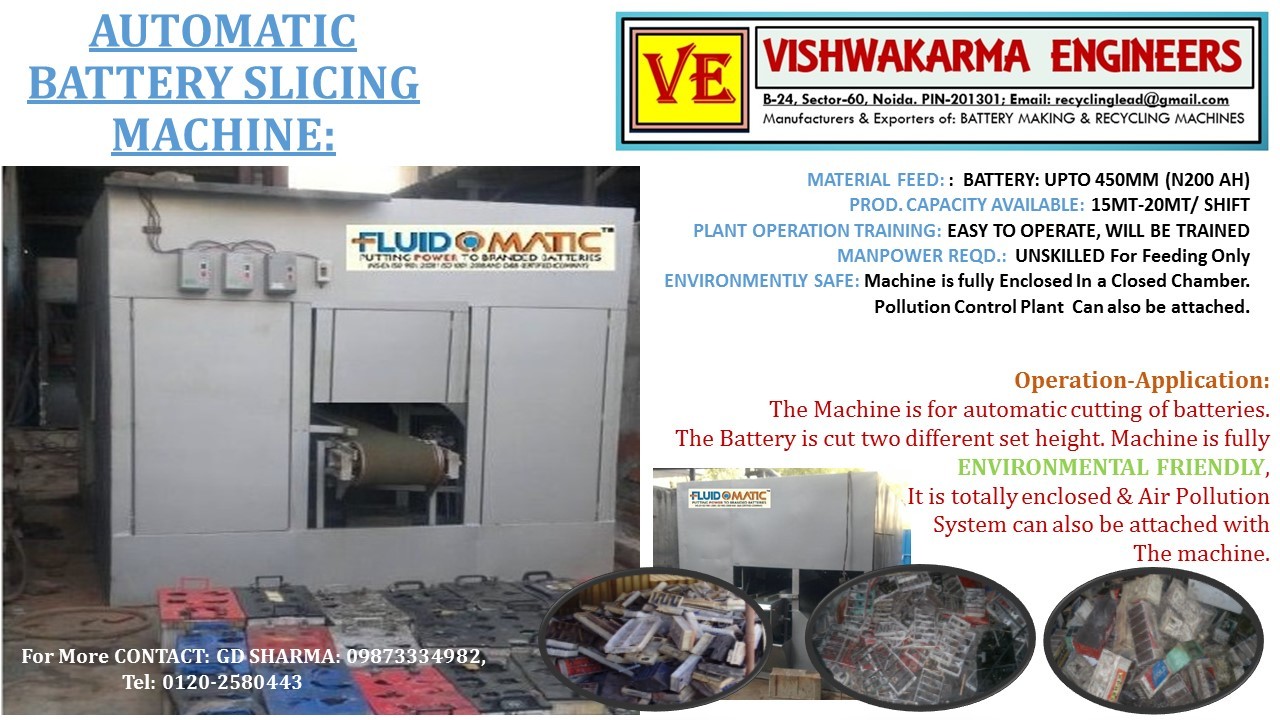

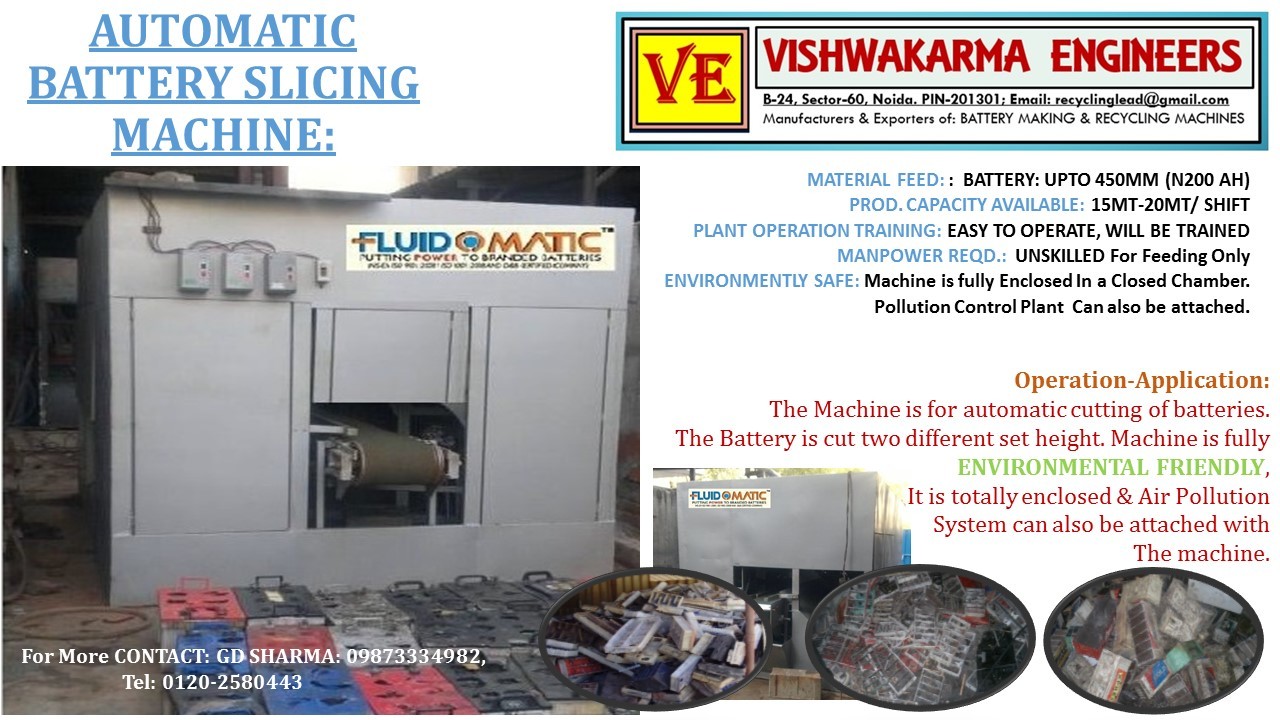

About Battery Cutting Machine

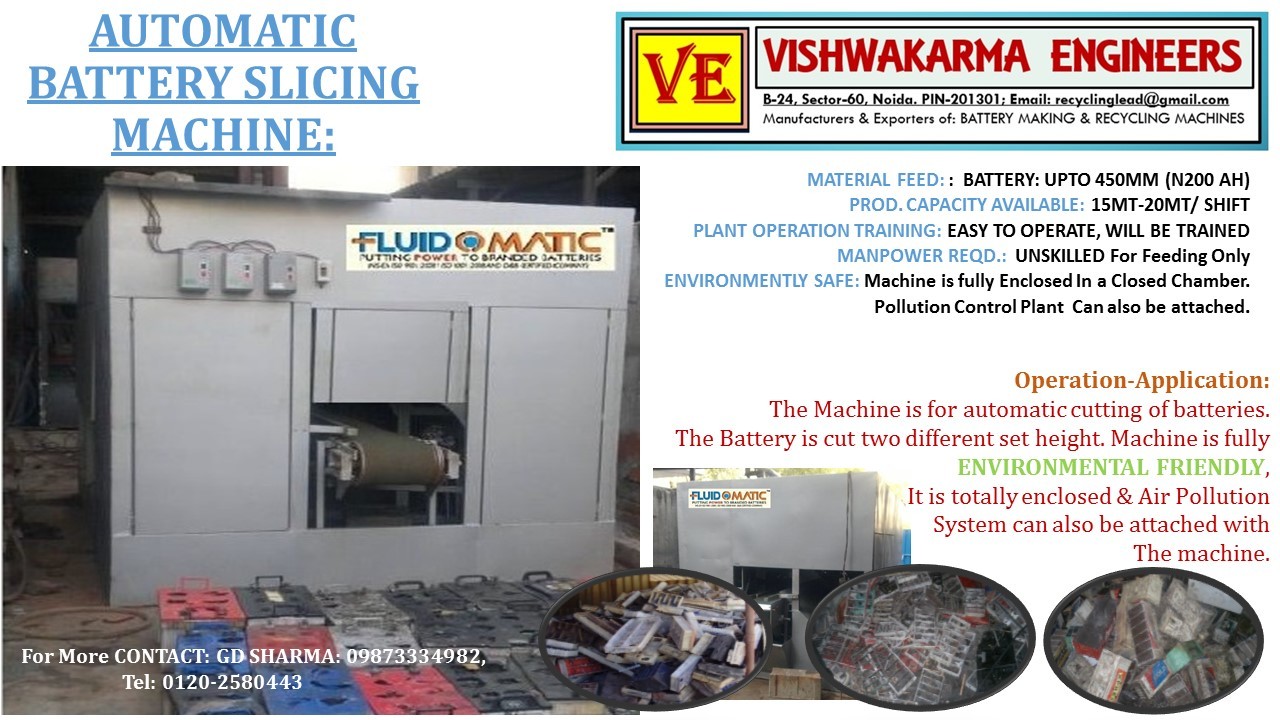

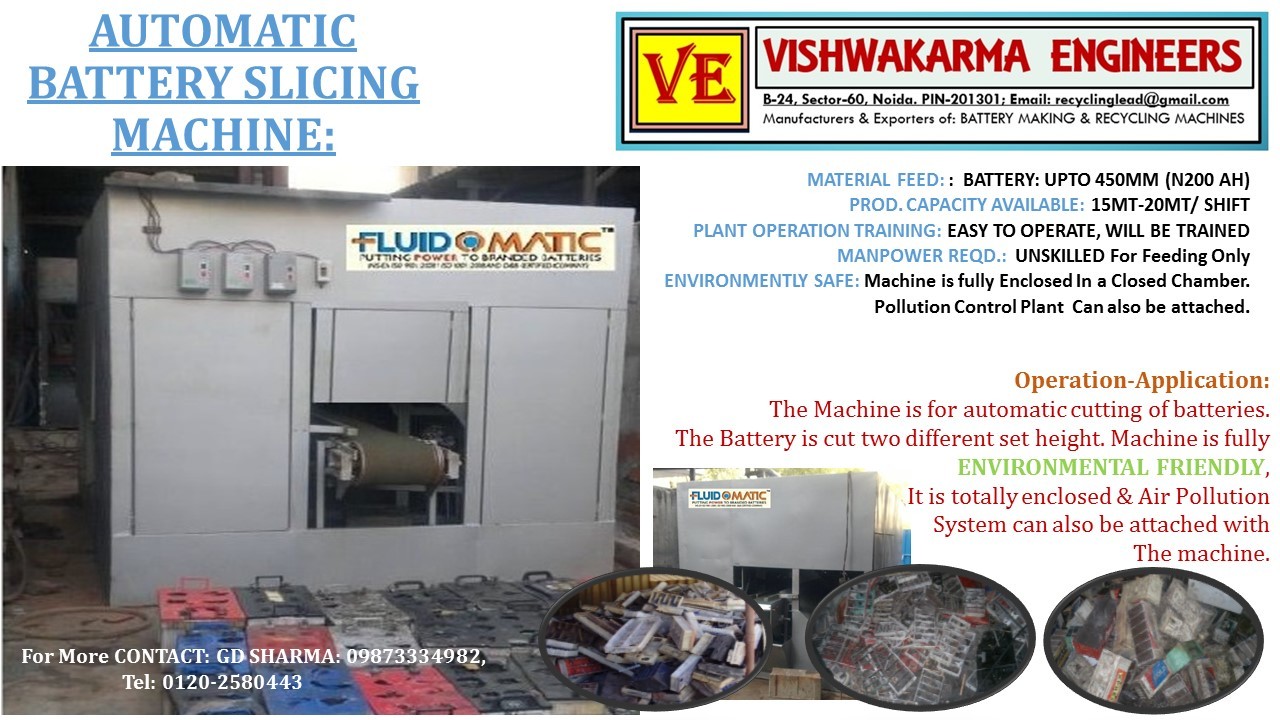

This machine has a automatic conveyor. Battery is placed on the conveyor. Width of Battery, need not to be set, battery to be placed to one side of conveyor. It can accommodate Battery up to Max.Width of 305mm. Most of Batteries are below this. Cutting height can be set by turning Rotary wheel over the machine. This wheel is visible in picture of machine. Scale is provided to set the height ofcutting. Conveyor takes the Battery in machine for cutting. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. No Fumes are coming out of the machine this ensureshealth safety of operator & labor loading the battery on machine. Normally Cutting is set at sealing line of lid. Max. of Automotive Batteries have approximately same height, say +-10 mm. Remaining Battery will come out of machine on Conveyor. If any Acid splash it will be inside the machine, therefore the acid can be taken out later on & sent to recycling in separate Acid Recycling Plant.

Thesesafeties saves exposure of workman from Lead Dust; It increases efficiency of organization reduceslead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility in Plastic Crushing Unit . Lead Dust is confined inside enclosure at the sametime water jets are provided by pre-fitted Pump for proper cooling to the cutting mechanism. Wateris collected in the bottom tank. This helps to separate Plastic Dust from Lead dust. Plastic dust floatsand lead dust is precipitated at the bottom. Hence this mechanized process becomes environmentallySound Method to cut the Battery for further separation.

Product details

| Belt Material | Nylon |

| Frequency | 50-60Hz |

| No of Cutting Blades | 1 |

| Phase | Three phase |

| Country of Origin | Made in India |

| Voltage | 415 V |

| Surface Finishing | Paint Coated |

| Power | 4.5 kW |

| Material | Mild Steel |

| Brand | Fluid-O-Matic |

| Capacity | 5 ton/hour |

Reliable High Precision Cutting

Equipped with high-grade alloy steel blades and a PLC-controlled hydraulic drive, the BCM-2100 offers accurate, repeatable cuts with 1 mm tolerance. Its water-cooled, automatic lubricating system and heavy-duty frame ensure durability and consistent performance even in demanding environments. This machine is ideal for battery recycling plants seeking scalable, precise, and safe operations.

User-Friendly Operation & Safety

The Battery Cutting Machine integrates a touchscreen HMI, enabling intuitive control and real-time monitoring. Key safety features, such as emergency stop switches and sensor lock interlocks, provide secure working conditions. The low noise level (<75 dB) and safety guards enhance operator comfort during floor-mounted installation.

Smart Data Management & Accessories

Data logging functionality via USB port allows operators to record and analyze cutting cycles. Included accessories - spare blade set and tool kit - help streamline maintenance. Connectivity through panel interface and robust corrosion-resistant components ensure the BCM-2100 is ready for demanding industrial use.

FAQ's of Battery Cutting Machine:

Q: How does the Battery Cutting Machine ensure high cutting precision?

A: The machine is equipped with high-grade alloy steel blades and a PLC control panel that maintains cutting accuracy within 1 mm. Its hydraulic drive and automatic lubrication system further support consistent, precise cuts.Q: What safety features are integrated into the BCM-2100?

A: Safety guards, emergency stop buttons, and sensor lock interlocks are built into the design to protect operators during use. The machine also operates with minimal noise levels and is CE certified for industrial compliance.Q: Where can the Battery Cutting Machine be installed and operated?

A: This floor-mounted machine is suitable for lead acid battery recycling plants and related industrial environments. Its robust construction and corrosion resistance make it ideal for heavy-duty usage.Q: What is the maintenance process for the machine?

A: Designed for low maintenance, regular checks are simplified with the included tool kit and spare blade set. Automatic lubrication and water cooling systems help minimize manual intervention and reduce downtime.Q: How is production monitored and data logged during operation?

A: Production cycles and operational data can be easily logged via the built-in USB port. The touchscreen HMI allows users to monitor parameters and track productivity in real time.Q: What are the main benefits of using the BCM-2100 in battery recycling?

A: Users benefit from fast cycle time (~3 seconds), energy efficiency (approx. 7 kWh consumption), high safety standards, precision cutting, and a durable heavy-duty steel frame. These features result in increased throughput and reduced operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Battery Plant Equipments Category

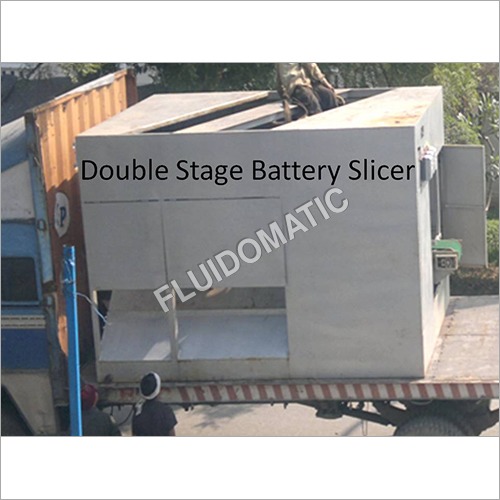

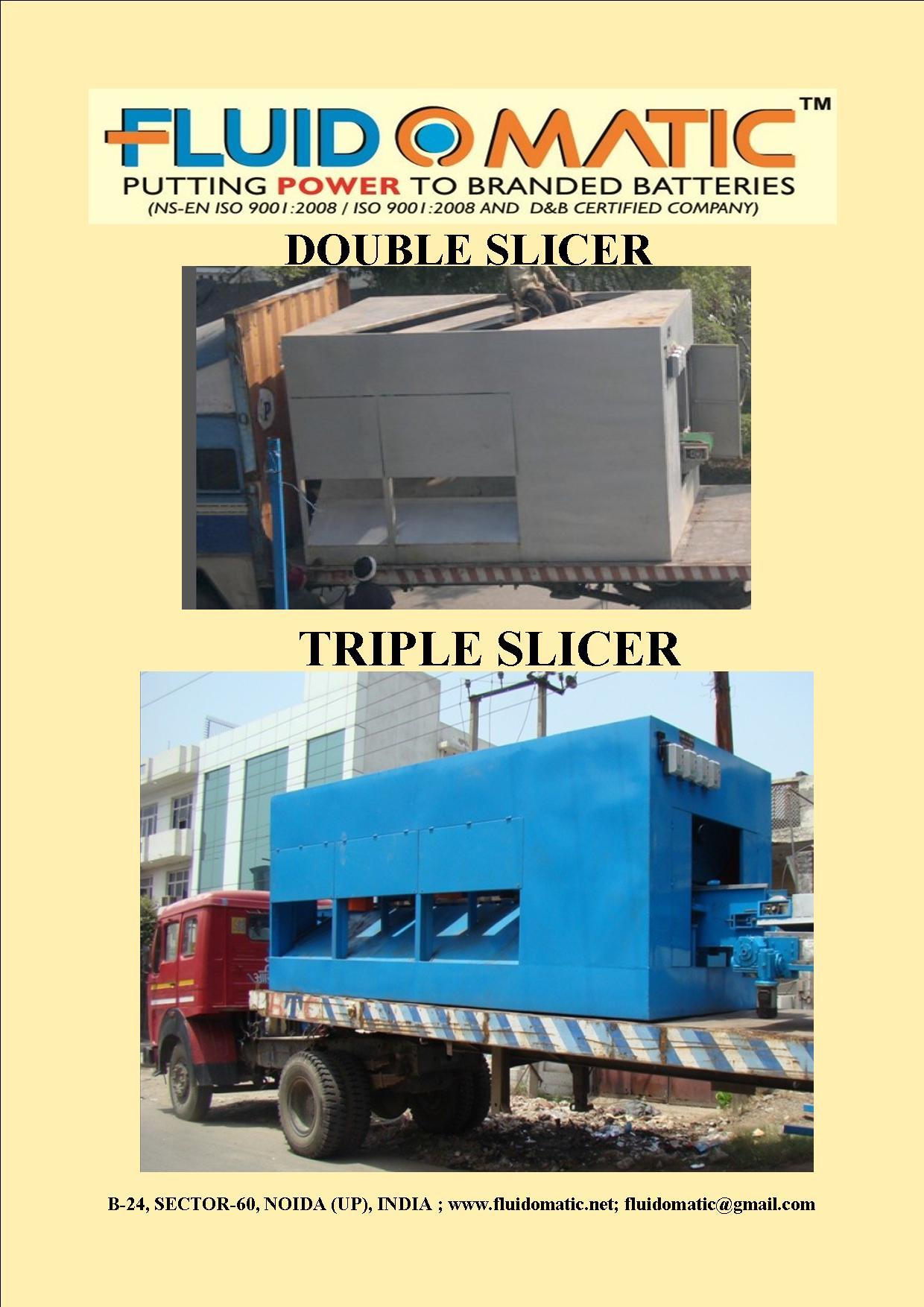

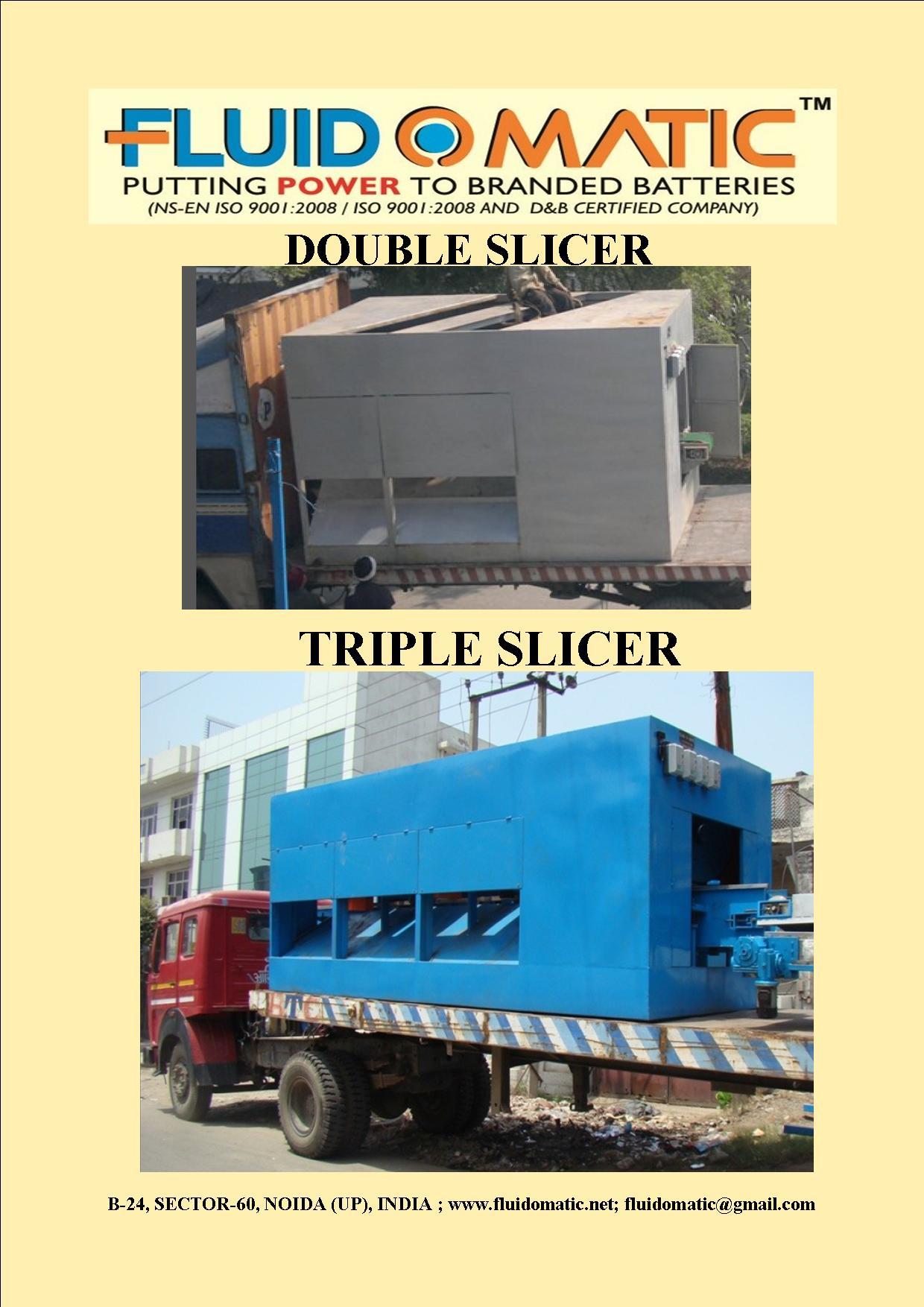

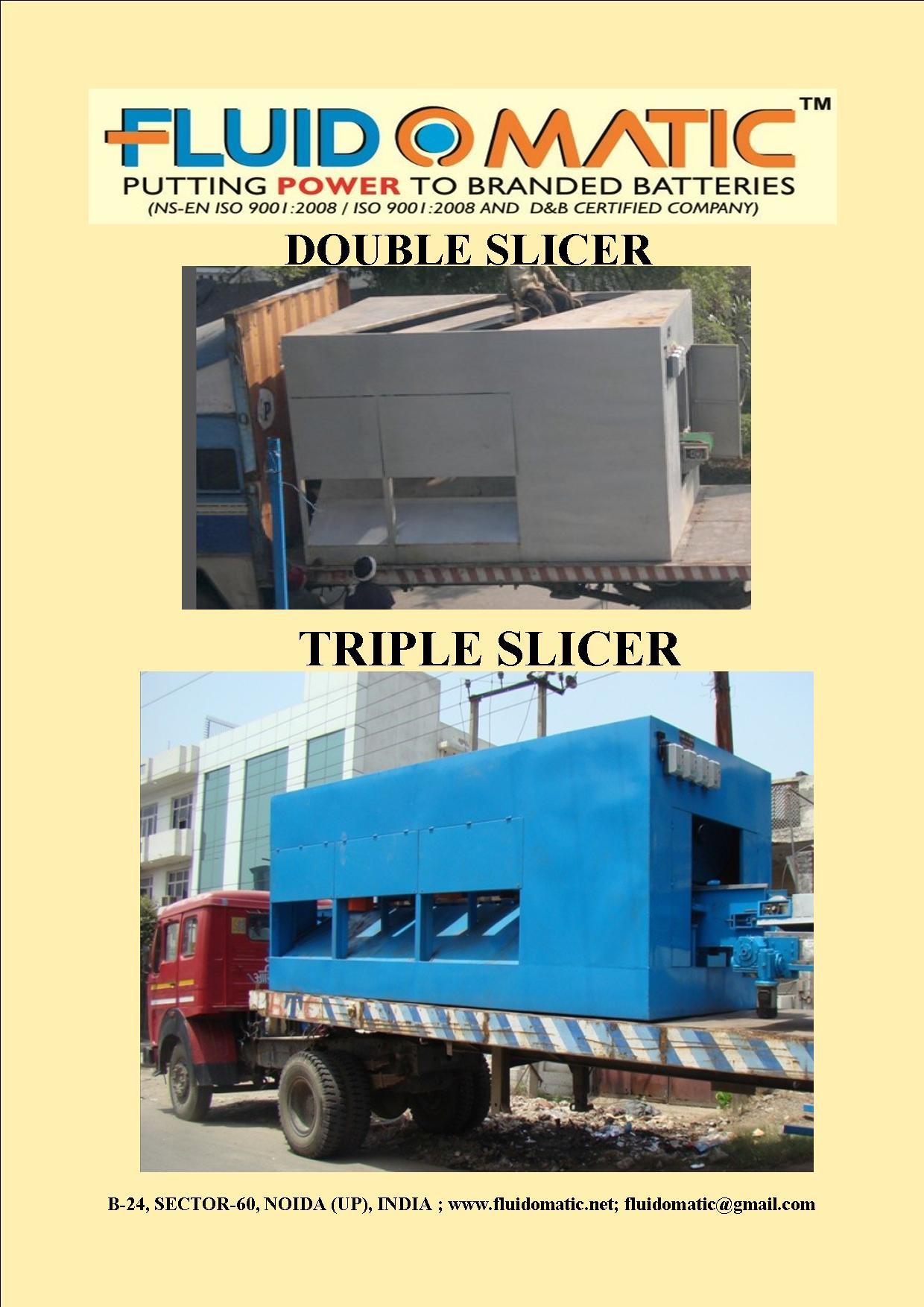

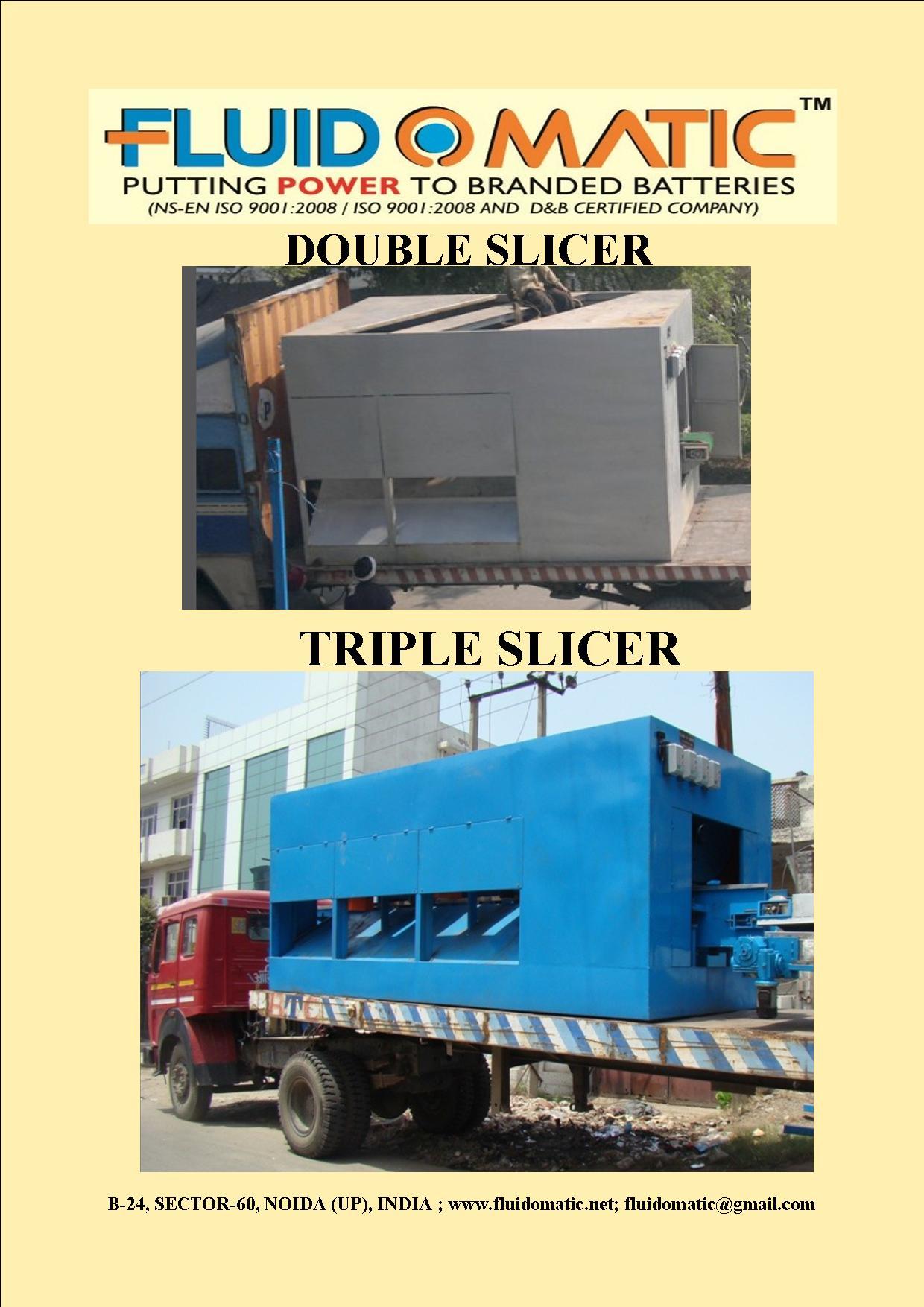

Triple Stage Battery Cutting Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Surface Treatment : Other, Powder Coated

Power Source : Other, Electric

Color : Green / Yellow (custom available)

Usage & Applications : Cutting and recycling of leadacid batteries

Acid Draining Attachment

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, CorrosionResistant Coating

Power Source : Other, Electric

Color : Blue/Silver

Usage & Applications : Draining acid from lead acid batteries

Refining Kettle

Price 500000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Surface Treatment : Other, Polished/Stainless Steel finish

Power Source : Other, Electric

Color : Metallic silver

Usage & Applications : Oil refining, edible oil processing

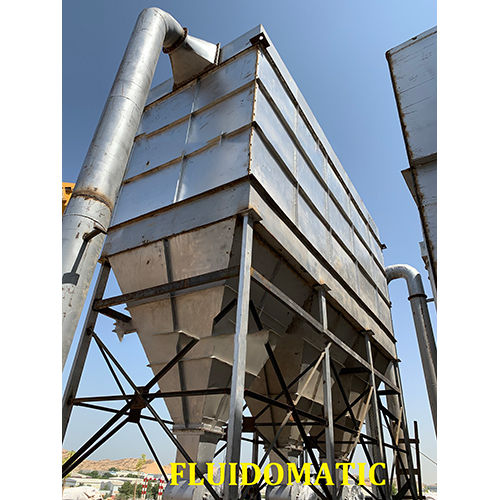

Air Pollution Control System Bag House Filtration System

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Polished

Power Source : Electricity

Color : Silver

Usage & Applications : Industrial

|

FLUIDOMATIC

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |