Rotary Furnace For Copper & Aluminum

Rotary Furnace For Copper & Aluminum Specification

- Features

- Energy efficient, low emissions, robust construction

- Connectivity Options

- Optional digital monitoring

- Power Rating

- Variable as per design

- Operating Temperature

- Up to 1350C

- Production Capacity

- 1-10 Ton/charge

- Drive

- Electric motor driven

- Lubricating System

- Automatic / Manual

- Frequency

- 50/60 Hz

- Machine Type

- Industrial Furnace

- Noise Level

- < 85 dB

- Frame Type

- Heavy Duty, Fabricated Steel

- Voltage

- 380V / 415V / 440V (Customizable)

- Control System

- PLC / Manual

- Cooling System

- Water / Air cooled

- Motor Power

- 3-15 HP (As required)

- Accuracy

- High melting efficiency

- Model No

- Custom/Standard Model

- Product Type

- Rotary Furnace For Copper & Aluminum

- Technology

- Rotary Melting

- Power Source

- Electric / Gas / Diesel

- Operating Type

- Automatic / Semi-Automatic

- Power

- Up to 100 kW or as per requirement

- Pressure

- Atmospheric / Customizable

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- Customized (Standard example: 3000mm x 2000mm x 2200mm)

- Weight (kg)

- Approx. 4000 - 6500 kg

- Color

- Grey / Blue / As per client requirement

- Usage & Applications

- Melting and recycling of copper & aluminum scraps

- Exhaust System

- Integrated Fume Extraction

- Safety Features

- Overheat Protection, Emergency Stop

- Burner Type

- Imported High-Efficiency Burners

- Changeover Time

- Rapid Turnaround between Batches

- Charging Door Type

- Manual/Automatic Sliding

- Loading Port Size

- Customizable as per requirement

- Fuel Efficiency

- Optimized for low fuel consumption

- Tilting Mechanism

- Hydraulic / Motorized Tilting

- Insulation Thickness

- 150-250 mm

- Applicable Scrap Types

- Wire, Sheet, Ingot, Casting Remelts

- Refractory Lining Type

- High Alumina / Fire Brick

- Charging Method

- Hydraulic Tilting / Manual Charging

- Flue Gas Treatment

- Provided with Wet/Dry Scrubber

Rotary Furnace For Copper & Aluminum Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 25 Days

About Rotary Furnace For Copper & Aluminum

Product details

| Capacity | Min 3 metric ton |

| Country of Origin | Made in India |

| Brand | Fluid-O-Matic |

| Automation Grade | Automatic |

| Max OperatingTemperature | 1200 Degree Celsius |

| Melting Time | 3-4 Hrs |

| Input Voltage (V) | 440V |

| Rated Power (KW) | 7.5 kW |

| Type Of Furnace | Tilt |

| Power Source | Electric, Gas |

| Melting Material | Aluminum, Lead |

Adaptable Refractory Lining for Enhanced Efficiency

Employing high alumina or fire brick lining, the rotary furnace maximizes thermal efficiency and resists corrosive elements found in scrap melting processes. The robust lining guarantees longevity, even under high operating temperatures up to 1350C, reducing downtime and maintenance cycles.

Customizable Operation and Charging Mechanisms

With hydraulic tilting and manual or automatic sliding doors, users have flexibility in feeding and discharging materials. The control system, available in both PLC and manual options, allows seamless operation while ensuring safety through features like overheat protection and emergency stop mechanisms.

Optimized Fuel and Emission Solutions

Equipped with imported high-efficiency burners and an integrated fume extraction system, the furnace delivers superior fuel economy and reduced emissions. Wet or dry scrubbers are provided for comprehensive flue gas treatment, aligning with environmental regulations and fostering workplace safety.

FAQs of Rotary Furnace For Copper & Aluminum:

Q: How does the rotary furnace optimize fuel consumption during copper and aluminum melting?

A: The furnace employs imported high-efficiency burners, advanced insulation up to 250mm thick, and a robust refractory lining to maximize heat retention. This combination significantly reduces heat loss, enabling efficient melting with minimal fuel usage, making the process both cost-effective and environmentally friendly.Q: What types of scrap materials can be processed in this furnace?

A: This rotary furnace is designed to handle a wide range of non-ferrous scrap, including wire, sheets, ingots, and casting remelts. Its versatile design makes it suitable for both copper and aluminum recycling across various industrial applications.Q: When is the best time to select a customized loading port size or door type?

A: Custom port sizes or door mechanisms should be discussed during the initial specification phase, allowing the manufacturer to tailor the furnace to your workflow, batch size, and material handling requirements. Early customization ensures efficient integration and operation at your facility.Q: Where is the rotary furnace typically installed and operated?

A: These industrial furnaces are commonly installed in metal recycling plants, foundries, and metalworking facilities that require high-throughput copper and aluminum melting and remelting operations. Site preparation includes ensuring access to required utilities and proper ventilation.Q: What process does the integrated exhaust and flue gas treatment system follow?

A: The system features integrated fume extraction and advanced wet or dry scrubbers that actively remove particulate, fumes, and other pollutants from the exhaust gases, ensuring compliance with environmental norms and promoting a safer working environment.Q: How does the hydraulic tilting mechanism contribute to furnace operation?

A: Hydraulic tilting automates the process of charging scrap and pouring molten metal, improving efficiency, safety, and turnaround time between batches. It allows rapid and controlled rotation, reducing operator strain and potential for spillage.Q: What are the main benefits of using this rotary furnace in industrial recycling processes?

A: Key benefits include high thermal efficiency, energy savings, low emissions, rapid batch changeover, robust safety systems, and adaptability to various power sources and operational modes. Its heavy-duty construction and customizable features make it a reliable solution for continuous industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Battery Plant Equipments Category

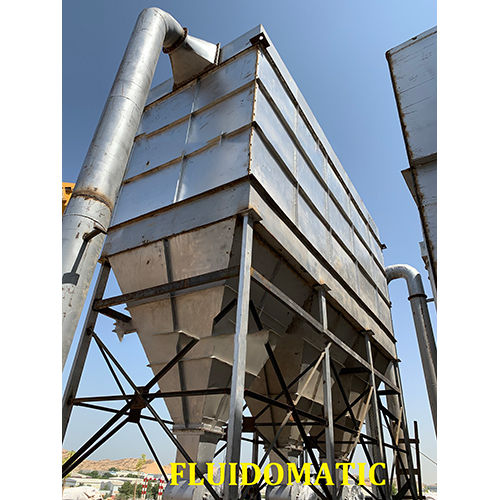

Air Pollution Control System Bag House Filtration System

Minimum Order Quantity : 1 Unit

Warranty : Yes

Operating Type : Automatic

Power Source : Electricity

Surface Treatment : Other, Polished

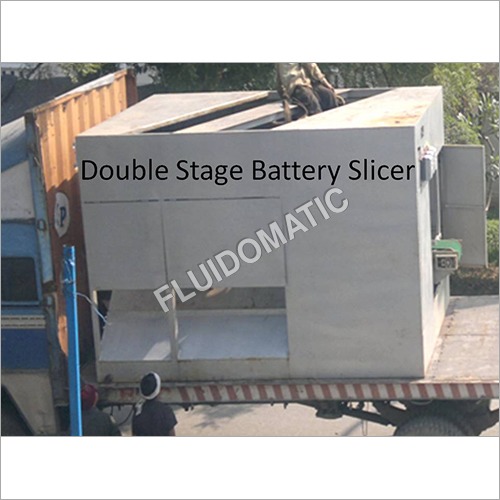

Triple Slicer Battery Cutting Machine

Minimum Order Quantity : 1 Unit

Warranty : Yes

Operating Type : Automatic

Power Source : Electricity

Surface Treatment : Painted

Human Body Cremation Unit

Minimum Order Quantity : 1 Unit

Warranty : Yes

Operating Type : Automatic

Power Source : Electricity

Surface Treatment : Other, Polished

Cremation Furnace Incinator

Minimum Order Quantity : 1 Unit

Warranty : Yes

Operating Type : Semi Automatic

Power Source : Electricity

Surface Treatment : Painted

Technology : Magnetism

|

FLUIDOMATIC

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |