Tilting Rotary Furnace

Tilting Rotary Furnace Specification

- Frame Type

- Robust Steel Frame

- Motor Power

- 15 HP - 30 HP

- Power Rating

- Depends on capacity (typically 60-120 kW)

- Noise Level

- Below 85 dB

- Production Capacity

- 2 to 15 Tons per Batch

- Features

- High Energy Efficiency, Low Metal Loss, Uniform Heat Distribution, Easy Tilting Mechanism

- Cooling System

- Water or Air Cooled Shell

- Machine Type

- Melting Furnace

- Voltage

- 380V / 415V, 3 Phase

- Drive

- Electric Motor Driven

- Frequency

- 50 Hz / 60 Hz

- Control System

- Digital PLC Controller

- Connectivity Options

- Optional Remote Monitoring

- Lubricating System

- Centralized Automatic Grease Lubrication

- Model No

- TRF-01

- Operating Temperature

- Up to 1450C

- Accuracy

- 1C (Temperature control)

- Product Type

- Tilting Rotary Furnace

- Technology

- Rotary Melting

- Power Source

- Electric / Fuel Fired

- Operating Type

- Semi-Automatic

- Power

- 60 kW - 120 kW

- Pressure

- Atmospheric

- Surface Treatment

- High Temperature Resistant Paint

- Dimension (L*W*H)

- 3800 x 1900 x 1850 mm (approx.)

- Weight (kg)

- 5500 kg approximately

- Color

- Metallic Grey

- Usage & Applications

- Melting and recycling of aluminium, lead, and other non-ferrous metals

Tilting Rotary Furnace Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 25 Days

About Tilting Rotary Furnace

Product details

| Body Material | Mild Steel |

| Surface Finish | Paint Coated |

| Country of Origin | Made in India |

| Brand | Fluid-O-Matic |

| Automation Grade | Automatic |

| Max OperatingTemperature | 1200 Degree Celsius |

| Melting Time | 3 Hrs |

| Voltage | 415 V |

| Rated Power (KW) | 7.5 kW |

| Type Of Furnace | Tilt |

| Power Source | Electric |

| Material Loading Capacity (T) | 8.5 Ton/hr |

Versatile Dual Fuel Operation

Our tilting rotary furnace comes with a dual fuel burner compatible with both gas and oil, making it adaptable to varying energy sources and ensuring continuous operation regardless of fuel availability. This flexibility suits diverse industrial setups and offers an excellent backup option when fuel supply constraints arise.

High Performance & Efficiency

Designed for optimal energy use, the TRF-01 features a water or air-cooled shell and centralized automatic grease lubrication, achieving up to 80% fuel efficiency. This results in lower operational costs and reduced environmental footprint while maintaining high production capacities of up to 15 tons per batch.

Advanced Control & Safety

The furnace leverages a digital PLC controller for precise temperature management with 1C accuracy, supported by a digital thermocouple. Its overheat protection, emergency stop, and comprehensive interlock system ensure the highest operator safety and quality control during every melt cycle.

FAQ's of Tilting Rotary Furnace:

Q: How is material loaded and discharged from the Tilting Rotary Furnace?

A: Material is introduced via the top loader, which is paired with a hydraulic tilter for smooth handling of large batches. Once the melting process is complete, molten metal is safely discharged using the hydraulic tilting system, allowing easy transfer to molds or ladles.Q: What types of metals can this rotary furnace process, and what is the batch capacity?

A: This furnace is suitable for melting and recycling aluminium, lead, and other non-ferrous metals, with a loading capacity of up to 15,000 kg (15 tons) per batch, meeting the demands of medium to large-scale foundries.Q: When and where is this furnace best installed for optimal performance?

A: For best results and longevity, the furnace should be installed indoors or in a covered industrial area. It is freestanding and skid mounted, making it suitable for factories, foundries, or recycling plants requiring robust and reliable melting operations.Q: What safety and control features are included with the TRF-01 Rotary Furnace?

A: The TRF-01 comes equipped with overheat protection, emergency stop, interlock systems, and a digital PLC controller. These features ensure operational safety and accurate temperature regulation throughout the melting process.Q: How does the furnace support high fuel efficiency and low energy consumption?

A: The furnace is engineered with a highly efficient dual fuel burner, advanced refractory lining, and features such as optimized exhaust systems and automatic lubrication, collectively delivering up to 80% fuel efficiency and low overall energy consumption.Q: What are the maintenance requirements, and how accessible is the unit?

A: Maintenance is streamlined through front and side accessible panels, allowing convenient servicing and inspection. The centralized automatic grease system ensures consistent lubrication, reducing manual intervention and downtime.Q: What are the main benefits of using this Tilting Rotary Furnace in industrial applications?

A: Key benefits include uniform heat distribution, low metal loss, flexible fuel use, high energy efficiency, reliable safety systems, and ease of operation. These attributes enhance melting productivity and reduce operational costs in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Battery Plant Equipments Category

Battery Heat Sealing Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Operating Type : Automatic

Usage & Applications : Battery manufacturing, Sealing battery containers

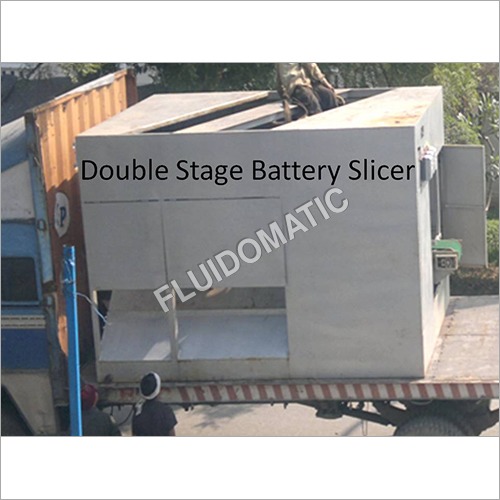

Triple Stage Battery Cutting Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Operating Type : Other, SemiAutomatic

Usage & Applications : Cutting and recycling of leadacid batteries

Acid Draining Attachment

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Other, Electric

Surface Treatment : Other, CorrosionResistant Coating

Operating Type : Other, SemiAutomatic

Usage & Applications : Draining acid from lead acid batteries

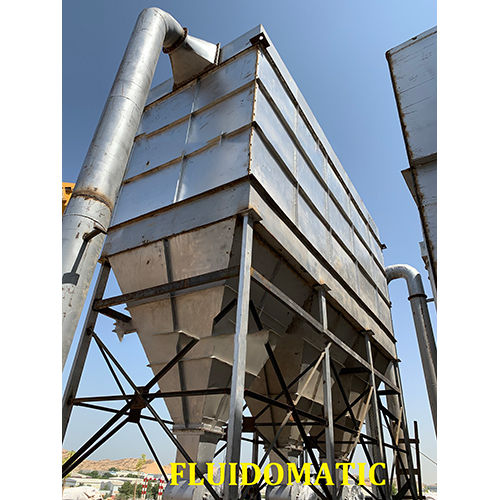

Air Pollution Control System Bag House Filtration System

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Surface Treatment : Other, Polished

Operating Type : Automatic

Usage & Applications : Industrial

|

FLUIDOMATIC

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |